Motor Cooling Methods (IC Codes) Explained

Motor Cooling Methods (IC Codes) Explained

Cooling is one of the most critical aspects of motor design. The International Electrotechnical Commission (IEC 60034-6) defines standardized cooling methods, known as IC (International Cooling) codes. Understanding these codes helps in selecting the right motor for specific applications and environments.

1. What Are IC Codes?

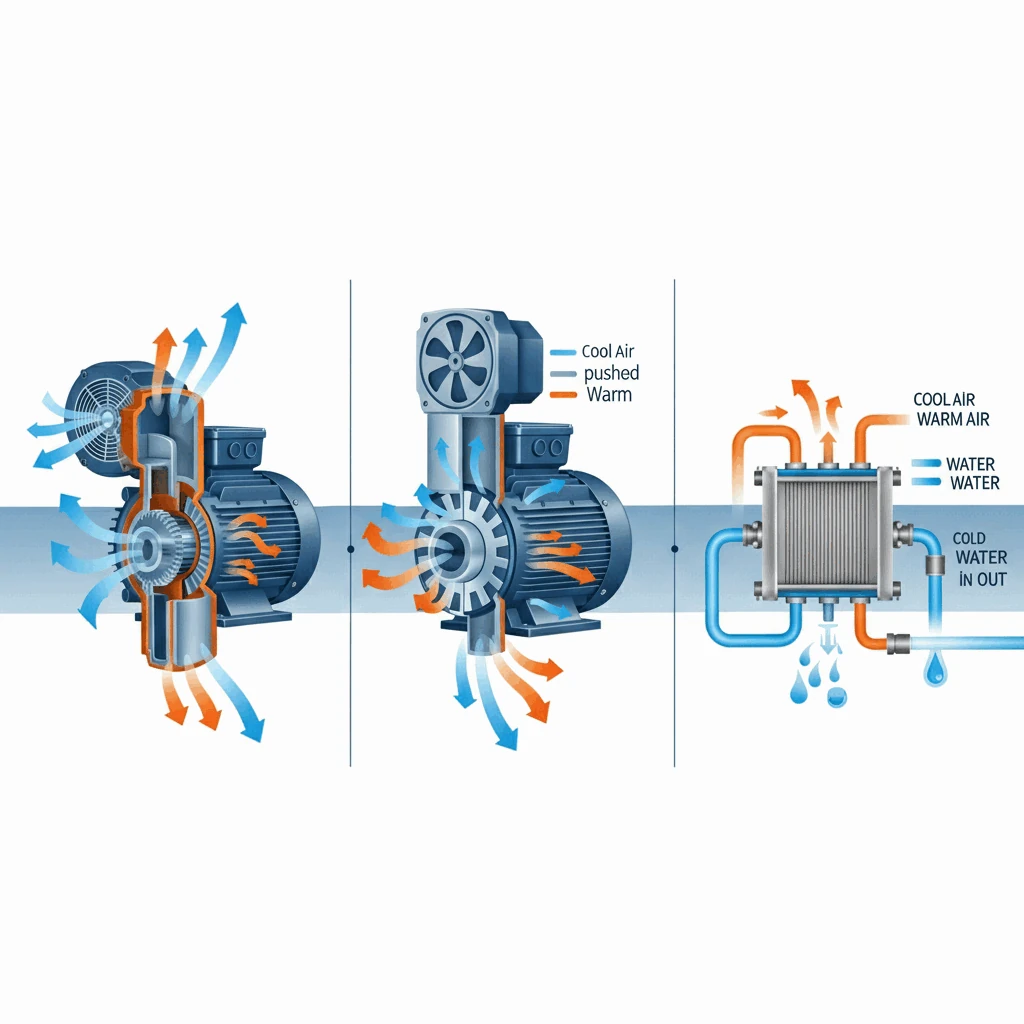

IC codes describe how heat generated in the motor is dissipated. They indicate the type of ventilation (natural, forced, closed, or open) and how air or coolant flows inside or outside the motor.

2. Common Motor Cooling Methods

- IC01 – Open Drip Proof (ODP): Air flows freely through the motor. Low cost, but unsuitable for dusty or wet areas.

- IC411 – Totally Enclosed Fan Cooled (TEFC): Standard industrial cooling. External shaft-mounted fan blows air over the ribbed frame.

- IC416 – Totally Enclosed, Forced Ventilation: External independent fan (separate supply) for continuous cooling, even at low speeds (ideal for VFD duty).

- IC418 – Totally Enclosed, Integral Fan: Dedicated auxiliary fan inside motor. Similar benefit to IC416.

- IC511 – Totally Enclosed Air-Air Heat Exchanger: Internal air circulates through a heat exchanger cooled by an external fan.

- IC611 – Totally Enclosed Air-Water Heat Exchanger: Internal air cooled via a water-to-air heat exchanger. Used in heavy-duty or confined applications.

3. Why Cooling Choice Matters

- Efficiency: Better cooling allows higher efficiency and power density.

- VFD Use: At low speeds, standard TEFC motors (IC411) may overheat—IC416 or IC418 is preferred.

- Environment: Dusty, humid, or hazardous areas require sealed designs (TEFC, heat exchangers).

- Service Life: Proper cooling prevents insulation breakdown and bearing failures.

4. Typical Applications

- IC411: General industry (pumps, compressors, conveyors).

- IC416 / IC418: VFD-controlled motors, hazardous zone motors.

- IC511: High-power motors in steel plants and cement mills.

- IC611: Motors in marine, underground, or enclosed environments.

5. CG Power Motor Cooling Options

CG Power offers a full range of motors with standard IC411 cooling and optional IC416 / IC418 for inverter duty. Larger frames and flameproof motors are also available with IC511 or IC611 cooling systems.

Final Thoughts

Cooling method selection directly impacts motor reliability and efficiency. When working with VFDs, hazardous zones, or high-power applications, choosing the right IC code ensures long service life. Bombay Engineering Syndicate provides technical support to match your application with the correct CG Power motor cooling method.

Contact us today to select the right motor cooling system for your project.

By: Manish Chandrani; +919825014977